Part 4 – Final Decisions

One of the hardest lessons in my life has always been knowing when to stop and say “good enough.” For a project like this, in which I’m examining a 50-plus year investment for our home, it feels like I’m dealing with some pretty high stakes. “Analysis paralysis” is the phenomenon in which you can’t come to a conclusion because there are always more factors to consider and study – I learned that term in grad school, but it shows up everywhere. Unfortunately, deadlines force us to move forward with an incomplete picture, making us take a position based on whatever information we have at the time, whether it’s a paper due for school or a leaky roof that needs to be replaced.

And this is a decision whose time has come.

In running a lifecycle analysis on a product, you want to consider – at a minimum – how the product is manufactured, what materials and energy are required to manufacture it, how it will be transported and packaged, how long it will last, what resources are required for maintenance over its lifetime, and what happens to it at the end of its useful life. Sometimes this information is is available; sometimes it’s not (especially for commercial products with proprietary information). For this post, I will summarize what turned out to be a month’s worth of research and calculations for three different roofing options: aluminum, steel, and asphalt shingles.

Transportation and Packaging

Without much useful information on transportation or packaging of the three options I examined, I left them out entirely, assuming that they were all manufactured domestically and packaged similarly. It is important to note that even though the shingles themselves may be manufactured domestically, the raw materials used may not be. The United States is the world’s ninth biggest producer of aluminum,[1] fourth biggest producer of steel,[2] and second biggest producer of asphalt/bitumen.[3] That means it is more likely that the asphalt in this analysis was produced domestically and the aluminum was produced abroad.

Image credit: [4]

However, since asphalt shingles are heavier than steel, and steel is heavier than aluminum, transporting the same square footage of shingles the same distance from manufacturer, to distributor, to contractor, to my home would result in the greatest carbon footprint for asphalt. Given both of those considerations, aluminum likely logs the most miles from start to finish (asphalt the least), but asphalt has the highest carbon footprint per mile traveled (aluminum the least). We would need more specific information on supply chain logistics to determine a break-even point on transportation footprint of materials, meaning I’m going to leave it out of the calculations, which may likely help the case for asphalt shingles.

Product Manufacturing

In an earlier post, I lamented no longer having access to the LCA software I used in grad school. Christian responded immediately by finding me a free, open version online.[5] It has a steep learning curve, but I’ve been able to get a slightly better idea of how resource intensive each of my options is. Again, I have very little information about the production energy required to manufacture each type of shingle. They all require rollers and a lot of heat, though the metal has to get hotter; metal also has extra steps with precision equipment stamping pieces into shape and baking layers of paint.[6],[7] I’m assuming there’s a higher energy requirement for manufacturing the metal shingles, but I don’t have specific numbers to plug into the LCA software for analysis. Leaving this step out of the calculation will most certainly help the case for metal shingles.

Raw Materials

At this point, it was starting to feel like my Starbucks cup LCA project from grad school all over again: we couldn’t get any process information from the company, so we had to guess in some places and completely remove parts of the lifecycle altogether, limiting our analysis to a very tiny piece of the whole. Fortunately, on this shingle analysis, I could at least look at the resource intensity for the major component materials of each type of shingle. (Note: I am not including paints or protective coatings here.)

My impact calculations for raw materials use the total estimated mass of product being used for our roof, based on an estimated mass by area for each.[8],[9] In roofing parlance, one “square” of shingles covers 100 square feet. Our roof needs approximately 17 squares of shingles.

(Average) 175 lbs/square x 17 squares of steel = 2,975 lbs (1,350 kg), Image credit: [11]

(Reference) 240 lbs/square (based on the asphalt shingles we are actually buying) x 17 squares of asphalt = 4,080 lbs (1850 kg), Image credit: [12]

It is also important to note that one of the touted benefits of a metal roof is that the materials are recyclable. Aluminum is is incredibly energy intensive to produce and far less so to recycle, which is why about 75% of all aluminum ever made is still in circulation today.[13] According to the metal roof company that was in the running, their aluminum shingles are 95% recycled material, and their steel shingles are 35% recycled material. The LCA software used a standard industry mix of virgin and recycled metals in the calculations for aluminum and steel, but I was unable to determine if that breakdown was the exact amount quoted to us by the metal roofing company. In any case, I assume it was close.

I assumed all virgin materials for the asphalt shingles, which were calculated using the following breakdown of component parts, based on 1) the EPA’s description of commonly used materials for asphalt shingles,[14] and 2) the closest material available in the software’s database: 22% bitumen adhesive compound (for asphalt cement), 15% glass fibres (for fiberglass felt), 25% dolomite (for stabilizer/filler), 38% inert rock (for aggregate).

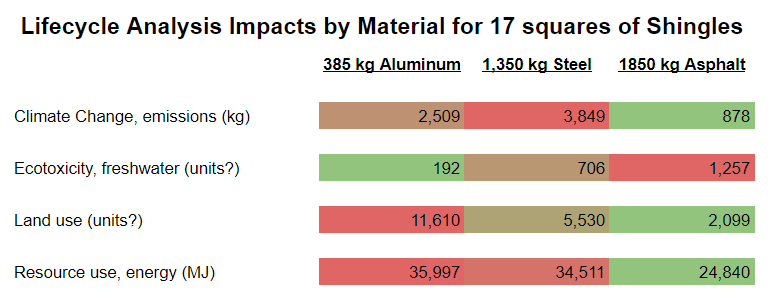

The LCA software can calculate totals related to energy inputs and pollution outputs, as well as other impacts like water system eutrophication, ionizing radiation, and ozone depletion. Many of these numbers came out to zero, I assume because I didn’t have information about the whole process (e.g. mining, smelting, refining, transporting, painting, coating, etc.) Since I didn’t have any of that information, I will summarize the most salient impacts related to the raw materials alone (knowing that transportation footprint could be higher for asphalt, and product manufacturing is likely more energy intensive for metal shingles).

(Also, the software was not forthcoming on how it quantified water and land impacts; we just know which material was the worst in each category.)

Based on this breakdown, the only thing that’s clear is that there are benefits and drawbacks for each option. However, from an energy input standpoint, virgin asphalt still appears to be a better option than either metal shingle. This calculation indicates that it takes more energy to produce and recycle the metal that will be used in metal shingles than it does to create brand new asphalt shingles.

(For reference, the EPA’s energy calculator provides the following equivalents shown above under resource use: 16.4 barrels of oil for aluminum, 15.7 for steel, and 10.6 for asphalt.[15])

Recycling Impact

Even though it would appear to take more energy to create metal shingles with recycled content than it would asphalt shingles from virgin materials, the recyclability of metal shingles remains a major selling point – after all, you aren’t creating waste that will go to a landfill. Presumably, recycling asphalt shingles would be even better for the environment – because why wouldn’t you recycle something if you could?

Unfortunately, there are no recycling options near us. One of our roofing proposals included transporting our old shingles to Michael Brothers,[16] where they would be recycled. I take all of our recyclables to Michael Brothers already, and I had never heard anything about asphalt shingle recycling. I called to confirm, and they were very helpful and straightforward about the fact that they do NOT recycle shingles – everything they get goes to a landfill.

When we informed said roofing contractor about what we had learned, they explored alternate options for asphalt recycling (with some encouragement from my husband). Unfortunately, many shingle recycling programs listed on the EPA’s website (last updated in 2012) are no longer in operation.[17] The closest operating recycling facility the roofing contractor could find was in Illinois, and to add recycling to the scope, we would need a special dumpster and a truck to take almost 2 tons of waste on a special trip.

The cost to do that was $500, which seemed incredibly reasonable given the extra effort, but I had to wonder about the carbon footprint of hauling the shingles that far. According to a carbon footprint calculator, we were able to determine that the impact of the round-trip drive to Illinois would result in approximately 3 metric tons of CO2-equivalent emissions,[19] similar to consuming 7 barrels of oil.[20] Assuming 210 lbs/square for the old, 3-tab shingles coming off of our roof, we would be trying to recycle about 1.8 tons of shingles, which would only save about 3.5 barrels of oil.[21] So ultimately, recycling the shingles would take more energy than it saved, and the decision to go with asphalt would require landfilling almost two tons of waste.

In Summary

Despite the advertisements saying that metal is the better option from a sustainability standpoint, I have been unable to find any evidence (either from a formal study or through my own calculations) that that is the case:

- The embedded energy required to create metal shingles is simply too great to be offset, even by recycling them at the end of their life. Recycling our old asphalt shingles turned out to have a net negative energy benefit, so they will be going to the landfill.

- Metal roofs can be marginally more energy efficient, depending on the roof slope and how they are installed, but the far better option (for us) was taking some (not all) of the cost savings from choosing asphalt and using that to weatherize our attic, saving energy and money.

- Coatings on any type of roofing material can be concerning and even pose harm to the local aquatic ecosystem, but the biggest red flag for me was the use of perfluorinated substances (PFAS) on most metal shingles. PFAS do not break down in nature or in the human body, and they are in many cases carcinogenic.

So in the end, despite my initial argument for metal nearly two years ago, some additional research brought me back to asphalt. And, although we had several quotes, we ultimately decided to go with a small, local business – less slick in their presentation and leaving much to be desired in customer service, but with 45 years of experience and willing to work with us through our various special requests.

Work will have begun by the time this post goes live, and hopefully I will never have to think about our roof again.

~

After following along with this research project, what would you pick for your house? Did anything in this series change your opinion? I’d love to hear your thoughts below.

Thanks for reading!

[1] https://en.wikipedia.org/wiki/List_of_countries_by_primary_aluminium_production

[2] https://en.wikipedia.org/wiki/List_of_countries_by_steel_production

[3] https://www.tigerbitumen.com/top-15-bitumen-producing-countries-in-the-world/

[4] https://www.carbonfootprint.com/productlifecycle.html

[6] https://www.youtube.com/watch?v=acynBfdNkVw

[7] https://www.youtube.com/watch?v=YPqiKU2M7EY

[8] https://www.fixr.com/comparisons/metal-roof-vs-asphalt-shingles

[9] https://www.reference.com/world-view/gaf-timberline-shingles-weigh-per-square-12927df500490977

[10] https://allstarroofsystems.com/aluminum-roofing/aluminum-shake-shingle-roofing/

[11] https://www.metalconstructionnews.com/articles/readers

[12] https://builderswarehouse.com/gaf-timberline-0670395-hd-lifetime-shingles-3333-sq-ft-hickory.html

[13] https://www.aluminum.org/industries/production/recycling

[14] https://www.epa.gov/sites/production/files/2016-03/documents/warm_v14_construction_demolition_materials.pdf

[15] https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator

[16] https://michaelbrothershauling.com/

[17] http://www.shinglerecycling.org/content/find-recycler

[18] https://www.literallydarling.com/blog/2016/06/22/create-proper-hobbit-hole-house/

[19] https://calculator.carbonfootprint.com/calculator.aspx?tab=4

[20] https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator

[21] https://www.forconstructionpros.com/asphalt/plants/article/10292429/quick-facts-about-asphalt-shingle-recycling-and-the-environment

0 Comments